Sustainability and the ICT Industry

Many of my previous articles, especially the last one on manufacturing and green labels, revolve around the Information and Communication Technology (ICT) industry. What I have noticed is the number of comments revolving around just what the ICT industry is comprised of and how that specifically relates to the common use of the word sustainability.

Many of my previous articles, especially the last one on manufacturing and green labels, revolve around the Information and Communication Technology (ICT) industry. What I have noticed is the number of comments revolving around just what the ICT industry is comprised of and how that specifically relates to the common use of the word sustainability.

First, some definitions: The ICT industry is comprised of mainly those industries that foster the transfer of information. Commonly it is synonymous with the IT industry but relates more to what has been dubbed Unified Communications including IT, telecommunications, audiovisual, and allied solutions that help a user to access, store, transmit, and manipulate information. Sustainability’s real meaning is meeting the needs of current generations without jeopardizing the ability of future generations to meet their own needs. It just has become synonymous with environmentally friendly, eco-friendly, or green.

As previously written about in this column, the impact of the ICT industry on the built environment has been steadily on the rise. This is both a blessing and a curse. On the positive side technology application can foster greater efficiencies within an environment through intercommunication of building wide systems. It can provide a mountain of data points that can either be evaluated or acted upon (or not) by either a human operator or through machine to machine communication. These systems can include HVAC, lighting, audiovisual, power demand, security and the like. As new challenges and ideas are generated we have the potential to increase the use of ICT solutions to manage and solve problems. Take projection systems for instance. By having control of and feedback from these systems many users now can better manage those assets, reduce operating costs, deploy systems as needed, and manage power demand increasing productivity of the users and providing a seamless technology based solution for communication of ideas.

This aspect of using ICT solutions to manage, maintain, and drive the work environment has moved into the C-suites and boardrooms globally. The key driver is the rapid increase in operating costs associated with an ever growing population of devices such as cell phones, lap tops, tablets, interactive displays, and teleconferencing systems to name a few. Outward, corporations see the positive benefits of the social responsibility aspects of a good corporate sustainability plan including ICT. Just to tick off some statistics that are prevalent in corporate thinking of sustainability strategies:

- The total contribution in 2012 (most recent available figures) to GHG emissions of the ICT industry is 2-3 percent and growing exponentially

- By 2020 the expected GHG contribution is 4-6 percent with even greater increases in economies such as China, India, Indonesia, Brazil, and other emerging markets

- The current Internet power demand is 30 gigawatts which is equivalent of 30 nuclear plants.

- By 2020 the estimated number of Internet connected devices is expected to exceed 50 billion.

- Data centers globally account for 280 terawatt hours and are in general 90 percent inefficient with their power use. Google, Apple, and others are looking at strategies to change this.

- Excluding ICT related emissions 97 percent of total global emissions could be reduced by up to 18 percent using ICT solutions we currently have available today.

The challenge in ICT sustainability lies in ensuring the ICT systems are designed, managed, and used in a way that minimizes the impact on the environment while meeting the needs and goals of the user. As described in last month’s article, sustainability goes into the manufacturing and sourcing of materials for ICT solutions as well as deep into supply chains to be as successful as possible. This is because, like most building materials, every stage of the ICT lifecycle impacts the environment in some way. Transportation, material outsourcing, green house gas (GHG) emission in the production process, and packaging are just a few examples of how ICT lifecycle can have a measurable impact on the environment. Little thought about other areas that can have huge implications can include even the construction of new facilities which may destroy habitat of various species or further degradation and deletion of local natural resources such as timber and water. The key four fundamental areas for the ICT industry are energy, GHG, e-waste, and water. Looking at cradle to cradle aspects of ICT technologies and conversion into the waste stream, recycling, repurposing, or reuse all become factors in the evaluation of the process.

Materials acquisition for instance require energy to either extract from nature which can produce toxic results or sourced upstream from another vendor from recycled materials. In some cases such as aluminum or glass which have been widely recycled for decades, this is a relatively easier process however; the materials at some point had to come from the earth.

Production of products can require large amounts of energy especially in the ICT industry with many components being manufactured by others often continents away using fuel in the process. This also incorporates the distribution of durable goods and the efficient of the selected mode of transportation or combination of modes such as truck to train to boat to truck to end user.

Even in the end users hands, embodied energy is required to operate and maintain equipment including the human factor of service technicians who operate help desks or do on-site repairs and maintenance. Additionally, end-of-life consideration for ICT solutions play a major role as often more energy is consumed to recycle than in the manufacturing process with an ever increasing stream of non-recyclable material reaching over crowded landfills.

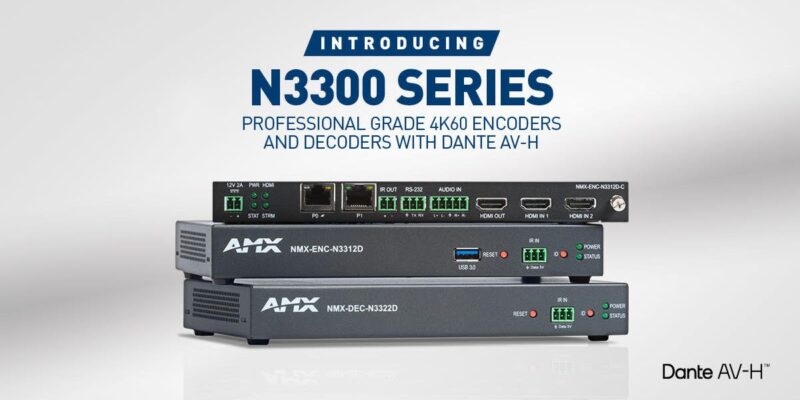

While there are many good example of ICT solution providers who have stepped up and lead the pack in sustainability one outstanding manufacture is Dallas-based AMX. Michael Carter, director of the company’s Integrated Building Solutions group provided me with some examples of how AMX works within the ICT industry towards sustainability. His points are as follows:

- AMX was one of the first ICT manufacturer to adopt RoHS compliancy within their product line (2005)

- Their products are based on energy efficient design and components. For example, their latest touch panel controls use 30 percent less power than previous generations and most of their core product line has low-power sleep or standby modes to significantly reduce power consumption when not in use minimizing vampire power draw.

- Their product line is developed around an infrastructure mentality being either card based or firmware based architecture to minimize disposable products and maximize upgradability.

- AMX has plans to move to Power of Ethernet for its devices to have greater efficiencies in power management.

- Their multi-function systems such as the Enova DVX line work to greatly reduce the power requirements for an entire ICT system.

- The company’s RMS and the NXD-PDU device are based on providing energy management and reduction.

- Packaging materials for their products are minimalistic, lightweight, made from recycled materials, and are 100 percent recyclable.

- AMX will gladly accept e-waste for recycling.

These are few ways one company is forward thinking and has embraced the notion that you can act responsibly in ICT manufacturing and be profitable. And as Michael indicated, there is always room to improve and he and his group are always striving to do that.