Zytronic investment enhances production capability at UK base

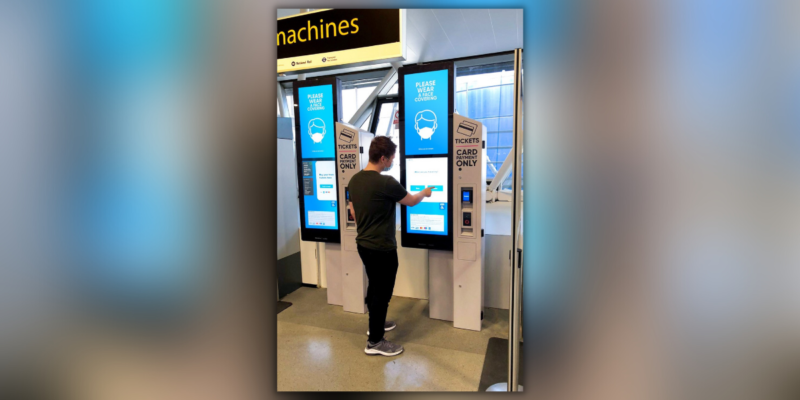

Zytronic, the specialist developer and manufacturer of touch sensors for medium to large format displays, has completed phase one of an ambitious investment programme that positions it to meet the rapidly increasing demand for touchscreens in all areas of society. Zytronic’s two proprietary technologies, Projected Capacitive Technology (PCT™) and Mutual Projected Capacitive Technology (MPCT™), are deployed wherever there is a requirement for people to interact with public electronic systems in a manner that is natural and intuitive, and where a resilient and robust solution is essential for continued reliable operation.

Zytronic, the specialist developer and manufacturer of touch sensors for medium to large format displays, has completed phase one of an ambitious investment programme that positions it to meet the rapidly increasing demand for touchscreens in all areas of society. Zytronic’s two proprietary technologies, Projected Capacitive Technology (PCT™) and Mutual Projected Capacitive Technology (MPCT™), are deployed wherever there is a requirement for people to interact with public electronic systems in a manner that is natural and intuitive, and where a resilient and robust solution is essential for continued reliable operation.

Capital expenditure for this first phase exceeded £1m ($1.5m) on plant and equipment to further enhance the quality and quantity of the company’s manufacturing output at its Blaydon, UK headquarters. Expenditure has covered increasing capacity, with the purchase of two new laminating machines, another flatbed washing machine to ensure the glass is crystal clear, and additional plotters, bonders and a new CNC router.

Zytronic has also invested in equipment to make the manufacturing process more efficient, including new robotic equipment, configured around a camera-based system, to enable more accurate placement of some of the integral electronic components. Additionally, new conveyor systems have been installed to move ultra large form factor glass touch sensors, up to 84 inches across, out of the clean rooms. The larger segment of the clean room in the main factory erected in 2001 has been refurbished to a higher standard and extended significantly.

Phase two, which should be completed during 2013, involves three aspects of expansion. The first, which was completed during April for £100k ($150k), involved the substantial expansion of the Research and Development (R&D) operational facilities, giving the R&D team much better and larger accommodation for manufacturing samples and testing new touch technologies and system enhancements. It includes a substantial clean room and an EMC testing facility.

The second aspect of phase two for £80k (US$120k) is expected to be completed in June. It involves the substantial upgrade to the screen printing facilities within Zytronic, including the installation of a new semi-automatic screen printing machine to accommodate the printing of touch sensors up to 60 inches across, and matching Zytronic’s internal thermal tempering capabilities.

Zytronic’s group finance director, Denis Mullan, commented: “Since we opened our third factory in Blaydon in 2008 to produce the ZYPOS™ range of touch sensor products, and despite the challenging global economic conditions, we have continued to invest in our R&D and manufacturing facilities in order to enhance our product lines and deliver the best quality and service to our international customer base.”

About Zytronic

Zytronic is the developer and manufacturer of a unique range of internationally award-winning touch sensor products. These products employ an embedded sensing element and are based around projected capacitive technology (PCT™) sensing. PCT offers significant durability, environmental stability and optical enhancement benefits to system designers of touch interactive, industrial, self – service and public access equipment. During 2012, Zytronic developed new know-how to create mutual projected capacitive technology (MPCT™), which enables multi-user and multi touch sensing in ultra large form factor sizes up to 84″.

Zytronic products are used in electronic displays for self service and information systems, ATMs and gaming machines, as well as by military, computer, telecommunications and medical OEMs, and are available from its network of worldwide distributors.

The company has its headquarters and state-of-the-art manufacturing facilities in Blaydon, Tyne & Wear in the UK. In addition to ISO-approved manufacturing, these facilities are home to Zytronic’s team of lamination, material science and electronics specialists who are responsible for ongoing product development in composite technology.

For more company information, visit Zytronic’s web site at www.zytronic.co.uk