Rock the Cradle!

Most often when design professional think about creating solutions that help improve the intended environment’s energy efficiency or work to reduce the overall carbon footprint of a space it is often just the immediate cause and reaction that is considered — if I use this product or solution than I reduce emissions by “X” amount. In the Information Communications Technology world we have the opportunity to go beyond that immediacy and look at the lifecycle of the technology as a whole.

Most often when design professional think about creating solutions that help improve the intended environment’s energy efficiency or work to reduce the overall carbon footprint of a space it is often just the immediate cause and reaction that is considered — if I use this product or solution than I reduce emissions by “X” amount. In the Information Communications Technology world we have the opportunity to go beyond that immediacy and look at the lifecycle of the technology as a whole.

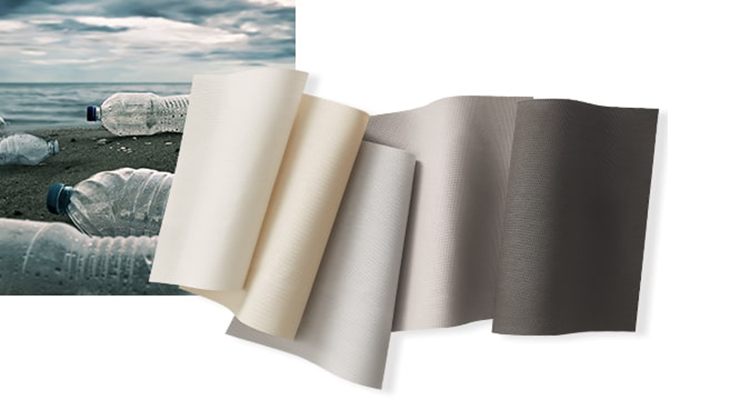

As I have written about many times before, electronic waste, or e-waste, is an ever expanding world problem and often times it is a team effort to combat. That team includes the technology systems designer, the integrator, and the owner/operator who can work together to create a solid cradle-to-grave plan for the technology systems implemented into a project. The STEP rating system included a pathway to accomplish this. Work was even being done to have a STEP rating for manufacturers and their products. Unfortunately this process is (hopefully) temporarily on hiatus.

Fortunately there is an organization that can help in the process. The Cradle to Cradle Products Innovation Institute (c2cPII). administers the Cradle to Cradle Certified Product Standard which has been around since 2010. The process came out of research and publications by William McDonough and Dr. Michael Braungart who in 1992 wrote The Hanover Principles: Design for Sustainability and Cradle to Cradle: Remaking the Way We Make Things published in 2002. This helped them create the framework for the Cradle to Cradle Certified Products Program.

The Cradle to Cradle Certified Product Standard gives designers and consumers an opportunity to select products that are verified by c2cPII to incorporate into their projects and environments. The process for manufacturers and industrial designers includes a vetting process that looks at five quality categories which include material health, material re-utilization, renewable energy and carbon management, water stewardship and social fairness. After an assessment and plan of action the product receives a level for each of the five categories ranging from Basic to Platinum with the overall rating being equal to the lowest rating in each of the categories. The product evaluation is performed by qualified independent organization trained by the institute and then the findings are reviewed by c2cPII who issues the final determination of whether the product meets the Standard requirements. Additionally the certification is reviewed every two years and the manufacturer must demonstrate a good-faith effort to improve their products to be recertified.

Quite often current manufacturers in the ICT community are already doing many of these things without the certification. Unfortunately there are also those who claim to be but are not really following a prescribed program that can be verified by a third party. Our industry is already accustomed to this type of process when complying with Underwriters Laboratories compliance or RoHS. As these certifications provide a level of confidence around specific aspects of product’s compliance with standards and regulations, the c2cPII program adds another level of green certification that can help to push a product into the forefront of a design teams design choice when they are looking to achieve their client’s goals of sustainability.

In looking deeper into the five quality categories it becomes pretty clear that the process is achievable and fair to manufacturers and consumers alike. Material Health looks at the actual materials and chemicals that are used in the manufacturing of goods and products and seeks ways to prevent likely exposure of humans and the environment not only during manufacturing but during ownership and eventual end-of-life. Materials Reutilization examines how products and processes can be developed in ways where everything from manufacture waste to reuse of the product as a whole or at the component level can be recycled, upcycled, ore safely returned to nature. Renewable Energy & Carbon management focuses on incorporating clean renewable energy into the manufacturing process and even the operation of the product. Water Stewardship takes into account water usage during manufacturing and its impact on the local environment in addition to any process involved with the deconstruction of the product at end-of-life. Lastly, Social Fairness assesses the commitment to honoring all people and natural resources regardless of location or geography in the creation, use, and disposal of the product. Basically — don’t ship your e-waste to third world country to be disassembled in an unenvironmentally sound way so the pollution doesn’t affect your local geography.

I would urge ICT industry manufacturers that have not explored this certification to look at the impact it will have on their core business as the built environment where the ICT systems live is ever increasingly more critical of how products impact the natural resources we share and live in.