Hybrid Optical Cables for High-Speed Digital Video

Technical Whitepaper: Hybrid Optical Cables for High-Speed Digital Video

Technical Whitepaper: Hybrid Optical Cables for High-Speed Digital Video

By: Cosemi Technologies, Inc. September 2015

I. Introduction

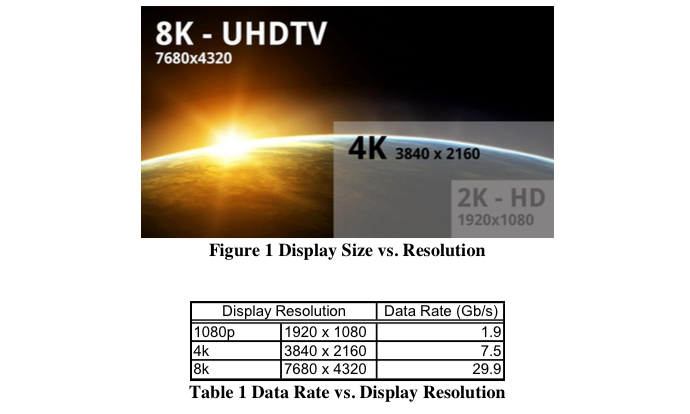

As video displays get larger in size, more pixels are needed to achieve the same video-playing quality (Figure 1). This leads to the display resolution progressing from the earlier 480 x 720 for DVD to 1080p for high-definition TV (HDTV) and now 4K and 8K UHD TV. Video transmission data rate increases accordingly with the increasing display resolution. Table 1 lists the data rate for some common high definition video playing format with 24 bit color depth and 30 frames/sec refresh rate. How to support video transmission for consumer applications at such a high data rate becomes a subject for many cable manufacturers.

II. Digital Video Interface Standards

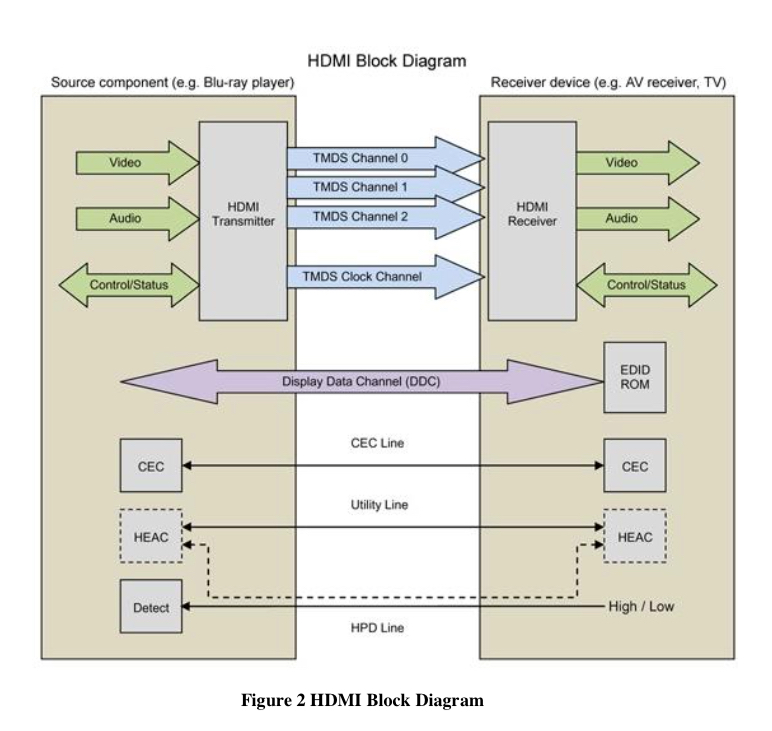

There are several digital video interface standards, including DVI, DisplayPort (DP), HDMI (High Definition Media Interface), HDBase-T, etc. HDMI is the most common digital video transmission protocol and is incorporated into almost every TV set today. Billions of HDMI ports are already available for use in the field. HDMI includes three high-speed TMDS (Transition-Minimized Differential Signaling) data channels for video and audio transmission, one TMDS clock, and a few low speed control channels, as shown in Figure 2. Control channels prepare the communications between a video player (source) and a video display (sink) to set the transmission guidelines before the video transmission. It also authenticates if the video to be played is a legitimate copy. An HDMI sink interface draws power from the source. Figure 3 shows the HDMI connector pinout, and the corresponding pin assignment is shown in Table 2 for HDMI Type A, Type C and Type D connectors.

To facilitate the higher display resolution at 4K, HDMI standard has evolved from HDMI 1.0 in 2002 to HDMI 2.0 in 2013. HDMI 2.0 supports 6 Gb/s per TMDS channel, with aggregated data rate of 1 Gb/s. HDMI 2.0 retains the electrical interface designed for HDMI 1.4. To allow for the use of HDMI 1.4 copper cables, HDMI 2.0 incorporates an electrical equalizer at the sink to compensate for the signal degradation over lower-grade HDMI connectors and HDMI copper transmission wires.

III. Active HDMI Cables

HDMI standard is defined over passive copper cables for connections of a few meters. As the data rate increases, the supported error-free transmission distance becomes shorter. There are applications requiring HDMI to support longer distances up to 100 m. In addition to the equalization at the sink as defined by the HDMI 2.0 standard, active copper cables incorporating additional pre-emphasis and post equalization chips in the HDMI copper cable bulkheads have been promoted to support up to 30 m extended distances for video transmissions. Technology to multiplex data and control signals into serial data for transmission over optical fibers at the source and demultiplex the data and control signals back into electrical signals at the sink has also been developed, allowing Optical HDMI to transmit the video over 100 m or beyond.

Active copper HDMI cables consume extra power as equalization chips are power hungry. The more powerful the equalization is – the more electrical power will be consumed. HDMI standard

allows 5V and 55mA power from the source and allows no more than 50mA over the power line to the sink when the sink is on, although many source devices may output more than 55mA current. This means an active HDMI copper cable in many applications requires an external power supply to function, thus becoming cumbersome.

An active optical fiber based HDMI cable does not require equalization, as OM3 multimode fiber bandwidth when paired with 850 nm VCSEL (laser) and GaAs photodiode technologies are sufficient to support 10 Gb/s over 100 m. When OM4 multimode fiber is used, the bandwidth will increase to 25 Gb/s over a 100 m distance. There are two distinct drawbacks with all fiber optical solutions for HDMI transmission. First, an external power supply is required to power the sink device as fiber cannot distribute electrical power from the source to the sink. Second, IC chips that multiplex data and control signals consume power and the standard compliant HDMI source may not have sufficient power to driver both electrical multiplexer and the VCSELs for converting electrical signals to optical signals. Therefore, external power will also be required at the source.

IV. Cosemi OptoHDTM Cable

Cosemi’s OptoHDTM hybrid optical/copper cable is the technology advancement that addresses higher data rate and longer distance video transmission, while being compatible with existing devices on the market. The implementation is transparent and requires no new learning or behavior changes by the users. In this technology, high-speed data and clock signals are transmitted over four multimode optical fibers supporting up to 100 m distances up to the HDMI2.0 limit. Low threshold, high speed VCSELs at the source consume power well within the HDMI standard limit and convert electrical data into optical data for transmission over optical fibers. Photodiode receivers convert optical data back into electrical data to send to the sink devices. The receivers require no bias power from either source or sink devices. Copper wires are preserved for the low-speed control signals to facilitate the communications between source and sink just like a regular copper HDMI cable. The copper wire for power from the source to the sink has also been retained. Therefore, OptoHDTM addresses high-speed data with fibers and low-speed control and power distribution with copper wires. The HDMI block diagram shown in Figure 2 remains valid without any changes.

Figure 4 shows the Cosemi’s OptoHDTM HDMI cables, supporting HDMI 2.0 up to 100 m. It requires no external power when in operation, just like a regular copper HDMI cable, but optional external power can be added if necessary for some special applications. It also supports optional HEAC, although such applications are not common.

Another advantage of Cosemi’s hybrid cable OptoHDTM solution is its flexibility for structured wire pulling over conduit when incorporating a Type-D micro-connector (Figure 5). Comparing to conventional copper based HDMI cables with 19 copper wires, there are far fewer and optimal number of copper wires and the necessary multimode optical fibers in the hybrid OptoHDTM cable. The cable diameter is about 1/3 of a Gauge 26 copper wire based HDMI cable. Therefore, the OptoHDTM HDMI cable is thinner and more flexible. It is also more robust than all-fiber based cables as the incorporation of copper wires reinforces the cable and protects it from breaking during the cable pulling through conduit.

OptoHDTM addresses current market needs based on the existing HDMI standard, which has been written on copper cables for short distance interconnection, as the video data rate keeps increasing for higher resolution displays and the copper centric standard is no longer appropriate for many critical applications. Future HDMI standard must leverage the optical fiber bandwidth while keeping backward compatibility. A hybrid fiber and copper cable solution provides a migration path for further exploration.

Cosemi’s hybrid cable technology may also find applications in other data interface applications, such as extended distance DisplayPort and USB 3.x that requires backward compatibility to USB 2.0. When applied to USB 3.x, high-speed data will be transmitted over optical fibers, while USB 2.0 channel will stay with copper wires. The implementation on DisplayPort will be similar to HDMI where high-speed data will be carried over optical fibers – while control and power lines will stay with copper wires, thus enabling the DisplayPort 1.3 to support an aggregated data rate of 32.4 Gb/s for 8K displays at extended distances at the lowest possible power – without resorting to an external power supply.

V. OptoHDTM Applications

1. Simple plug-and-play application for extended distance. Note the following parts for an HDBT solution vs. a single HDMI Cosemi cable

- HDBT Transmitter

- HDBT Receiver

- HDMI Copper Cables(2)

- Category Cable

- External Power Supply

There are two main stumbling blocks prohibiting the implementation of HDBaseT. The first is the common stumbling block from an installation perspective. Today, HDBaseT is primarily used to transmit HDMI signaling, point-to-point, using a transmitter and receiver, over a category 5 or 6 cable, up to 100 meters. In this application, some of the most common stumbling blocks are: cabling – dependable performance requires the use of quality cables, both the category cable and the HDMI leads; form factor – space limitations, aesthetics, ease of use, and incorporation of other signal types that may necessitate the HDBaseT devices being in wall- plates, rack-mounted, or very small boxes; and power – accessing power on both ends of the run or just one end? If power is available on only one side, is it on the transmitter or receiver end? The second stumbling block is from an industry growth perspective. While adoption of HDBaseT is accelerating, it is as a point-to-point extension solution.

2. According to Garry Dukes, Director of Product Management, C2G – The following is a great example of where Cosemi OptoHDTM cables can be used for multiple HDMI sources through a switch and then out to a display.

3. Long distance multi room solutions can be achieved by using an HDMI matrix switch to send video signals to various rooms via a Cosemi HDMI cable.

4. Medical Use.

- Sending video signals through medical booms in the operating room.

- Limited space available – so the benefit of using a Cosemi OptoHDTM will allow one toeasily pull the cable through the boom to the displays.

- Cable is EMI/RFI resistant. Only fiber optic cables are immune to EMI & RFI.

- Cosemi OptoHDTM is a low-cost alternative to the current use of fiber optic extenders.