Design Thinking And How It Can Help Build A Better, More Sustainable Business Practice and Supply Chain In The Technology Industry

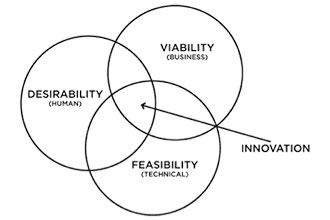

Design Thinking – It is not really a term that is familiar to many people but has significant impact on our daily lives and, more importantly, how we can develop better products and solutions in a more efficient and sustainable manner. Unlike the scientific method, which defines the question, then works towards a solution after breaking down ideas through destructive analysis, design thinking starts with the solution and works backwards using constructive and destructive methods to clarify what the problem actually is and builds up ideas through a more creative process. The methodology spans across many disciplines and industries and works well for both product development and intangible constructs.

Design Thinking – It is not really a term that is familiar to many people but has significant impact on our daily lives and, more importantly, how we can develop better products and solutions in a more efficient and sustainable manner. Unlike the scientific method, which defines the question, then works towards a solution after breaking down ideas through destructive analysis, design thinking starts with the solution and works backwards using constructive and destructive methods to clarify what the problem actually is and builds up ideas through a more creative process. The methodology spans across many disciplines and industries and works well for both product development and intangible constructs.

Basically it revolves around a few key elements each which seem simple but can go awry quickly if constraints or negativity is involved.

- Identifying the goal so you can define the problem

In design thinking, observation matters as does a willingness to suspend judgment of ideas as the right problem is identified. It sounds relatively straightforward; however, this is probably the most critical of the steps in the process. It requires the team to find their inner child and always question every aspect of the problem as it relates to the goal. There has to be intense cross-examination of the constraints and filters set upon the possible solutions so as to narrow the definition of the right problem to solve. In other words you, need to define the box before you can break out of it. Words and ideas are important as they will frame the conversation resulting in creative solutions. An example may be asking the question what features in projectors reduce the most energy that we put in classrooms. An answer may be don’t use projectors? - Many options and opportunities

It is an easy trap to fall into to rely on what you did last time to solve a problem especially when it produced positive results and you have a short time frame. Design thinking requires you to conceive of multiple solutions with no constraints or negative feelings (budget, materials, etc.) for consideration allowing them to be judged equally. More often than not, we are unaware of the subconscious constraints we place on ourselves. By freeing up obstacles, opportunities appear. Having multiple points or sources of input helps in creating these opportunities. For instance, it may be better to attack a problem with a team of ten people for a day then two people for a week. We also (as technology designers) have opportunities to use both 2D and 3D tools allowing both a visual and even textural demonstration of ideas. In my world of architecture we quite often use Google’s SketchUp in this manner during a design charette to brain storm building forms and site locations to help create opportunities to reduce energy. - Thinning the herd

So now you have a whole bunch of ideas. Now it is time to evaluate, combine and nurture the most promising ideas. This methodology gives rise to a conducive environment for growth and experimentation. Several trips through this phase may be required to narrow down the right opportunities always checking back on what the original goal is. - Winner, Winner, Chicken Dinner!

Having gone down the road less traveled and assessed the relevant opportunities it is time to commit resources towards the goal. Often the benefit of this process is the discovery of new strategies, methodologies in process, use of materials and so on that should be cataloged and further explored for potential uses in solving other problems.

So how can this benefit what we do in technology and how can it help to imbibe sustainability within our processes, products and services? Besides the obvious of better products and new solutions, there is a real opportunity to explore design thinking methodology when it comes to achieving a measure of sustainability within our industry. Applying these principles to what we do as systems designers, integrators and even end users will work towards a positive outcome environmentally, socially and economically. We have already started down this path with the creation of the Sustainable Technology Environments Program (STEP) rating system, which gives construct and rubrics to a more sustainable outcome. The solution was identified and we worked through the process to achieve the outcome. What is a result of this work is a STEP rating system for Information Communication Technology (ICT) Manufacturers. To me one challenge is how deep they take it within their own organization and their supply chain. Will it be enough to stop at the loading dock door with raw materials coming in and products going out?

To look at this further, we should look at Wal-Mart’s recent execution of its Sustainability Index for its suppliers. To be successful in its defined goal of bringing an improved measure of sustainability to 70 percent of its products customers buy most often by the end of 2017, Wal-Mart integrated sustainability into its core business practices and reached further into its supply chain to drive the productivity loop increasing customer’s trust and their profitability. This didn’t just happen because the wind blew. Wal-Mart assembled a team of participants (The Sustainability Consortium) with diverse backgrounds including academics, employees from the stock rooms and elsewhere, representation from manufacturers from over 200 merchandising categories, consumers and many sustainability industry experts to brainstorm ideas and opportunities to develop a 15-question Sustainability Supplier Assessment. This assessment helped Wal-Mart understand where its vast number of suppliers stood on sustainability issues and it allowed the manufacturers the opportunity to increase awareness on sustainability topics related to distribution and manufacturing. They also identified the goal at the onset of achieving a more sustainable and profitable supply chain.

To look at this further, we should look at Wal-Mart’s recent execution of its Sustainability Index for its suppliers. To be successful in its defined goal of bringing an improved measure of sustainability to 70 percent of its products customers buy most often by the end of 2017, Wal-Mart integrated sustainability into its core business practices and reached further into its supply chain to drive the productivity loop increasing customer’s trust and their profitability. This didn’t just happen because the wind blew. Wal-Mart assembled a team of participants (The Sustainability Consortium) with diverse backgrounds including academics, employees from the stock rooms and elsewhere, representation from manufacturers from over 200 merchandising categories, consumers and many sustainability industry experts to brainstorm ideas and opportunities to develop a 15-question Sustainability Supplier Assessment. This assessment helped Wal-Mart understand where its vast number of suppliers stood on sustainability issues and it allowed the manufacturers the opportunity to increase awareness on sustainability topics related to distribution and manufacturing. They also identified the goal at the onset of achieving a more sustainable and profitable supply chain.

The Sustainability Index helped to identify improvement opportunities unique to particular product groups as well as provide a roadmap for the manufacturers to guide their suppliers further down the supply chain. As a result, buyers for Wal-Mart are being trained and compensated based on their own sustainability performance as it relates to the best interest of the company, consumer, shareholders and most importantly the planet. Through this four key indicators to bring meaningful change have been identified including:

- Climate and Energy

- Materials and Resources

- Ecosystems and Human Health

- People and Community

So to circle back to the ICT industry and STEP for manufacturers the real question will be how this will be perceived by the industry and will there be an expectation as a result of or in addition to Wal-Mart’s experience in supply chain management. By identifying the goal of what we as an industry want and what are customers are demanding in terms of sustainable products and processes will help to keep the momentum going.

STEP for ICT manufacturers started this by identifying a solid mission: “To establish, implement and recognize sustainable practices in our administrative and manufacturing operations, facilities and products.” This includes ICT manufacturers, their suppliers, distributors, system integrators, and value-added resellers (VARs). Similar to the creation of both the STEP rating system, as well as Wal-Mart’s Sustainability Index, a variety of participants has been convened to study the goal and identify the problems to reach they end game. Through the process, which they are close to completing, four major areas have been identified, including what certifications the company has, programs it offers or participates in, how it manages waste and how it manages its environmental impact. Looking at the list of areas in the mission statement is a good indication of the size of the challenge facing manufacturers that are willing to participate. It will be interesting to see who will make the effort and how much demand there will be from design consultants, end users, and possibly governmental regulatory agencies in the future. I am excited at the prospects as a co-creator of the STEP rating system and certainly will be keeping a close watch.

Have you used design thinking methodology to work through a process or product idea and how has it helped to make you, your company, or your product/service more sustainable?