Amorphous Nano-Pixel Displays That Are Thinner Than Human Hair Are Coming — Seriously!

Plasmonic metasurfaces are being developed for use in future flat panel displays. These are basically scalable electrochromic nanopixels using plasmonics and their color gamut and high spatial resolution blows away even the best OLEDs we have today — by a factor of between 400 and 1000. Right now, according to a research paper published in the May 10th issue of Scientific Advances magazine, these plasmonic coloration cannot be perfectly tuned and still require expensive lithographic techniques.

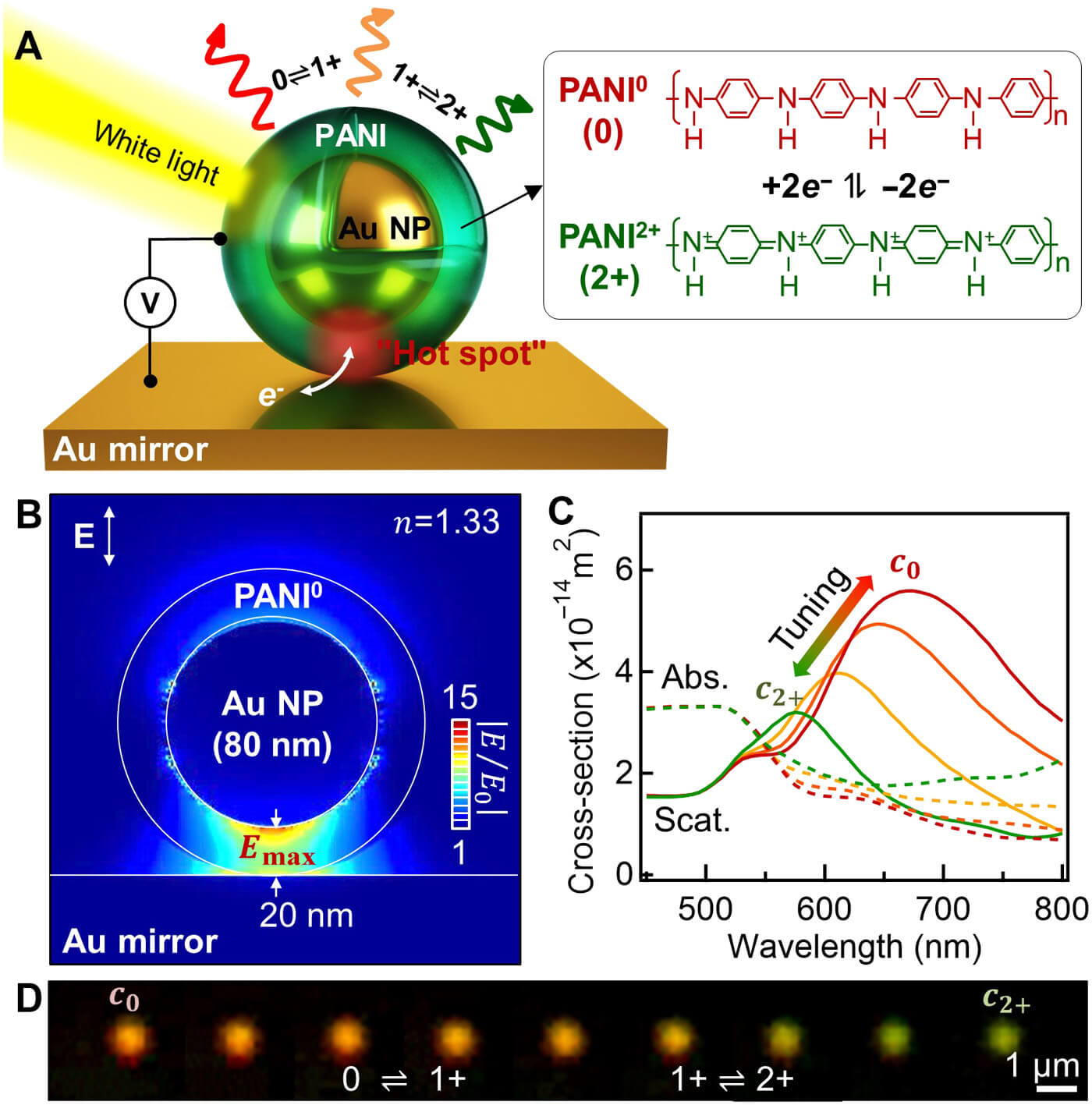

A group of engineers from the NanoPhotonics Centre and the Nanoscience Centre at the University of Cambridge presented a case last month for scalable electrically driven color-changing metasurfaces constructed using a “bottom-up solution process that controls the crucial plasmonic gaps” and fills them with an active medium.

What does this all mean?

Well, the implications are major as it means we could eventually put these nano-pixels into any surface (concrete in buildings, woven into clothes you wear or carpet, fabrics, glass, etc.), which would mean that nearly any surface would eventually inherently and natively be a display surface. The smallest pixels yet created – a million times smaller than those in smartphones, made by trapping particles of light under tiny rocks of gold – could be used for new types of large-scale flexible displays, big enough to cover entire buildings, says the research group from Cambridge.

This announcement actually reminded me of the one I received back in the late 1990s when OLEDs were being described as an eventuality — and, here we are, 20 years later and OLEDs are blowing people’s minds with image quality. So, I am excited to imagine this 20 years from today!

The color pixels, developed by a team of scientists led by the University of Cambridge, are compatible with roll-to-roll fabrication on flexible plastic films, dramatically reducing their production cost.

At the center of the pixels developed by the Cambridge scientists is a tiny particle of gold a few billionths of a meter across. The grain sits on top of a reflective surface, trapping light in the gap in between. Surrounding each grain is a thin sticky coating which changes chemically when electrically switched, causing the pixel to change color across the spectrum. The team of scientists, from different disciplines including physics, chemistry and manufacturing, made the pixels by coating vats of golden grains with an active polymer called polyaniline and then spraying them onto flexible mirror-coated plastic, to dramatically drive down production cost. The pixels are the smallest yet created, a million times smaller than typical smartphone pixels. They can be seen in bright sunlight and because they do not need constant power to keep their set color, have an energy performance that makes large areas feasible and sustainable.

The pixels could enable a host of new application possibilities such as building-sized display screens, architecture which can switch off solar heat load, active camouflage clothing and coatings, as well as tiny indicators for coming internet-of-things devices.

If you are so inclined to understand the details on how it works, read their paper here.