Organically Certified Displays: OLED May Become Cheaper (And More Organic)

Recent research has discovered a new approach to Organic Light Emitting Diodes (OLED) that may reduce or eliminate the need for the rare (and costly) metals needed to manufacture OLED displays. Thanks to collaborative research at Regensburg, University of Bonn, University of Utah, and MIT — the cost and impact of OLED displays will be going down. How is this possible? Read on if you want more than the headline.

Recent research has discovered a new approach to Organic Light Emitting Diodes (OLED) that may reduce or eliminate the need for the rare (and costly) metals needed to manufacture OLED displays. Thanks to collaborative research at Regensburg, University of Bonn, University of Utah, and MIT — the cost and impact of OLED displays will be going down. How is this possible? Read on if you want more than the headline.

What are Organic Light Emitting Diodes?

Organic Light Emitting Diodes (OLEDs) are becoming the building blocks of choice for consumer displays for their ability to generate deep blacks and bright colors without the need for a global backlight (thus being thinner than technologies like LCD). One of the drawbacks of OLEDs is the expense since they require rare metals during manufacturing and the cost of those metals is significant.

Typically, iridium and platinum are required in OLEDs — driving demand for mining operations in remote locations of the world and increasing the amount of Iridium that, ultimately, needs to be disposed of without reaching our drinking water (hopefully).

How is it possible to reduce the cost and impact of OLED displays?

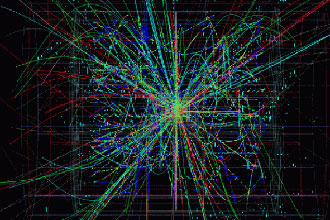

Let’s first recall how OLEDs produce images. Their operation is based on a fundamental principle of atomic and molecular physics called absorption — electrons moving from one energy state to another emit a fixed amount of light. I won’t go into all the details here, but if an atom needs an electron (referred to as an electron hole) and “falls” into that hole, a photon is emitted. Conversely, when an atom absorbs a photon, it can move an electron into a higher energy state. OLEDs trap organic molecules between two conductive plates (a cathode and anode). An electrical current is applied across the plates and through the trapped organic molecules. The molecules neighboring the cathode are “given” electrons while the anode pulls electrons from the organic molecules nearby. The result is a two-layer sandwich with extra electrons in one half of the material and electron “holes” in the second half. When electrons fall into these holes, a photon is emitted, creating light. By controlling the application of current, you can create small regions of light (pixels) in your display.

It turns out that the color (wavelength) of the photon that is emitted is related to the atomic number of the atom containing the electron hole. The wavelength can be estimated by the Rydberg Formula that relates emitted color to the atomic number and contains the quantum energy constant. Using this principle, manufacturers will make use of different organic elements to create the color primaries that need to be emitted (think red/green/blue ). Finally, to control brightness levels, a stronger current is applied to force more photons to be emitted over shorter periods of time. Now you have controllable color and brightness over a spatial region that contains the organic elements — the price of entry in creating a display.

Most of my readers are familiar, at a high level, with the advantages of OLED — each element in an OLED emits it own light that can be switched on and off. This means better black levels, bright spatially localized color and manufacturing advantages when you don’t have to include a backlight technology like LCD requires. For example, OLED can be built into curved displays.

However, the requirement for rare metals has kept costs high. Why the need for the metals? It turns out that my description of atomic emission is not yet complete. In order to decide if an atom will release a photon when the electron falls into place, the quantum spin of both the electron and the “hole” need to be taken into account. Spin is an atomic property that, at a marco level, gives rise to magnetism and, similarly, governs how very small things, like electrons, interact. Because an electron has two possible spin states, there are four possible spin combinations between an electron and the corresponding “hole” it falls into. Only one of these combinations will emit a photon, while the other three emits energy in the form of heat. Yes, you heard me right, left unchecked, your OLED TV would only transfer 1/4th of its energy into light and the rest would just warm your living room. In order to avoid this problem, the carbon molecules are combined with the hydrocarbon molecules to modify the spin states of the holes. Creating a statistically greater mix of states that will generate light. Very clever — but expensive.

The new research I mentioned is exciting in that it makes use of the fact that, if an electrically excited state is left that way long enough, the spin state will flip into a state that will always emit a photon. So, if a hole can be created but not filled for a few milliseconds, it is almost always going to be found in the correct (more energy efficient) spin state. This sounds like a short amount of time, but keep in mind that it typically takes on the order of nanoseconds for an electron to find and fall into an electron whole. The new approach under development, then focuses on ways to stall this process. The technique that they report in a paper in Angewandte Chemie uses peculiarly shaped organic molecules that are able to trap the free electron long enough that the spin state of the hole will have flipped prior to absorption. It’s very clever, and has great promise.

Obviously, given how recent the results are, it’ll be some time before manufacturers are able to take advantage, and more time after that before you’re able to buy a TV based on the new class of materials. It’s exciting to see how quickly the science of displays continues to advance and to those who think the AV industry is stagnant, I suggest that you take a careful look at where OLEDs may take us in the next few years.